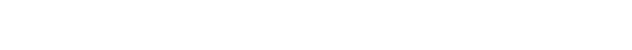

Cold-End Coating System

OVER BELT COLD END COATING

This equipment provides glass container cold-end coating treatment, spraying glass containers with a dissolved polyethylene wax emulsion, thus creating an external coating on the glass container with good sliding capacity.

CHARACTERISTICS

Strong portic frame

Bridge with transverse sliding guides for the spray gun trolley. The spray gun has lengthwise displacement, which is automatically synchronized with belt speed

Spraying precision between rows of bottles

Transversal and longitudinal motions made by SEW motor reducer with position control

Spray-gun manual height regulation and automatic lift when passage of the spray-gun between rows is obstructed

Pneumatic spray-gun control equipment

Electric panel with PLC, frequency inverter and PC connection

Operation: Manual, Semi-automatic and Automatic.

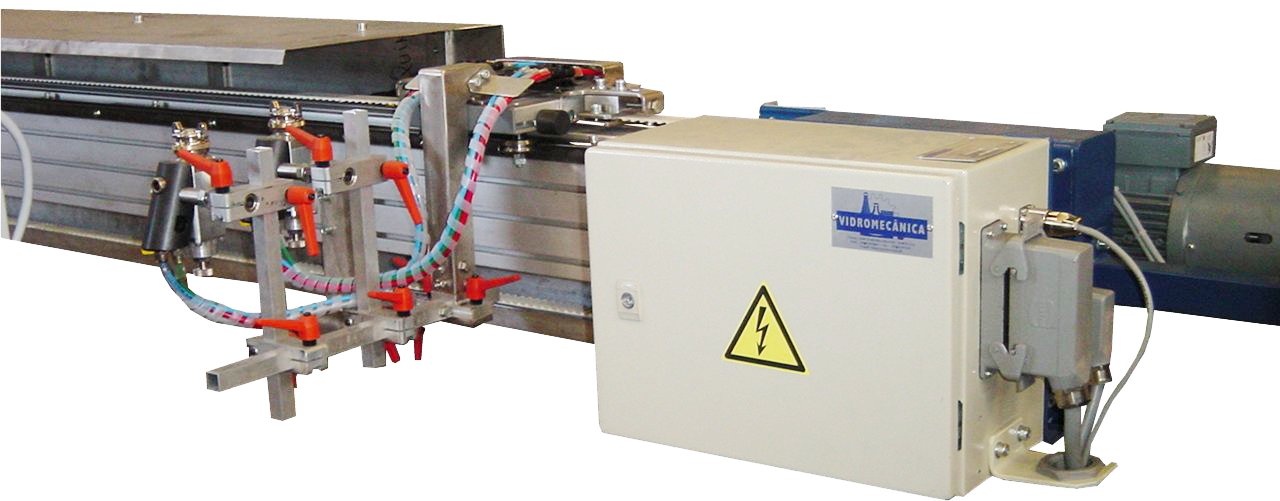

UNDER BELT COLD END COATING

This method of spraying may be used with overhead spraying to provide additional continuous coating of bottles, or when used alone, to avoid entry of the spray mixture into the jar or bottle.

Lehr belt width up to 6,0 meters

CHARACTERISTICS

Bridge under the lehr belt conveyor equipped with sliding guides for spray gun trolley. Spray gun trolley with vertically set up spray guns

Pneumatic set up for spray guns

Control panel with transversal speed adjustment by frequency inverter

Operation: Manual, Semi-automatic and Automatic.